New milling process and equipment:

|

Characteristics |

Traditional atomization technology |

new atomization technology |

|

|

Cost |

powder yield rate |

35-40% |

>60% |

|

Ar gas consumption |

800-1000m ³/h |

20-30m ³/h |

|

|

Gas consumption cost |

80-120 yuan/kg |

20 yuan/kg |

|

|

Quality |

powder morphology |

approximately spherical<90% |

approximately spherical>95% |

|

hollow powder |

many |

almost no |

|

|

satellite balls, |

many |

almost no |

|

|

Inclusion control |

without slag and gas removal is inevitable, In the future |

strict inclusion control can meet aviation requirements |

|

NNew materials:

3D printing equipment series:

An industrial metal 3D printing system with ultra-high production efficiency and easy operation:

Automatic switching of dual component warehouses for continuous printing production

Continuous circulation of overflow powder and adaptive uniform wind field

Permanent filtration system, batch import of process parameters

Open process parameters and variable layer thickness printing

Slicing software is highly compatible, with printing sizes ranging from 100-1500mm

The advantages of 3D printing in the field of new energy vehicles:

Free design, integrated forming, no need for welding

Reduce weight and optimize product structure

Uniform wall thickness and improved heat dissipation effect

Short manufacturing cycle and greatly improved service life

It is the development direction for the upgrading of new energy vehicle motors in the future

Collaborative product display:

Lithium titanium foil

In order to provide electrode materials with lighter weight, higher corrosion resistance, and better mechanical properties such as strength, toughness, and elasticity, our company has carried out rolling of titanium alloy ultra-thin foil materials. Currently, we have developed titanium alloy ultra-thin foil materials with a width of 105mm, a thickness of 5 μ m, and 3 μ m. Samples have been sent to Ningde Shidai for testing, and the results feedback meets the design requirements (strength>380MPa, elongation>3%). Compared with the current use of 6 μ m copper foil, the weight has been reduced by 3/4, energy density has doubled, and volume has been reduced by 1/2. The test has been passed in Ningde Times soft pack batteries.

-

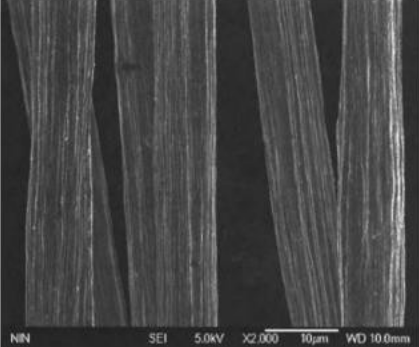

Titanium fiber felt

Titanium fiber felt, also known as titanium fiber diffusion layer, is a core component of PEM electrolysis water hydrogen production system. It has excellent corrosion resistance, better gas-liquid mass transfer ability, and optimal electrolysis performance. It is the most ideal diffusion layer for PEM electrolysis water hydrogen production system, and currently mainly relies on foreign imports.

The company has achieved breakthroughs in various processes such as the preparation of 15 micron titanium fibers, automatic pneumatic wind mesh for titanium fibers, and vacuum sintering. It has developed fifth generation samples, which fully meet or even exceed the performance indicators of high-end titanium fiber felt in industrial PEM electrolytic cells, and can replace imports.